Manufacturing

Toll & Own Manufacturing Facilities

Soliteint manufacturing plant was brought to life in 1997, after successful 30 years, with a state-of-the-art manufacturing facility, equipped with the most cutting edge technology that allows us to work with a vast range of manufacturing and filling capabilities.

A product manufactured in Soliteint is more than a mix of carefully measured ingredients. It is the result of constant collaboration between highly specialized teams and high-end machinery. We have specialized teams managing each stage of the process from R &D to production to marketing and sales to ensure proper execution and follow-through.

Our groups’ backbone being pharmaceutical guarantees the highest level of quality standards. We work with a vast range of mixing capabilities including creams, lotions, liquids, semi liquids, powders, toothpaste, sticks and alcoholic products. Our filling capabilities include Tubes, jars, sachets, and bottles.

Over time Soliteint’s relentless commitment to quality portrayed through its stringent guidelines enforced by quality control and assurance specialists, has earned it a solid international reputation for being dependable and efficient. We use the SAP System to ensure a consistent efficient performance & workflow. And we implement and improve the quality management systems and assure all the processes in the factory are verified, validated, and complying with the most recent accreditations such as ISO 9001/2015 and cosmetics GMP ISO 22716. The Soliteint cosmetics facility operates in compliance with current good manufacturing practices (GMP and GLP) & applies the Lean Six Sigma Methodology.

Our Services

Production

Research & Development

Supply chain

Quality control

On-going stability

Regulation Affairs

Turn your idea into a complete product!

Some of our Toll Manufacturing Partners

Research & Development

The R&D department at Soliteint Cosmetics has been the formula designer and developer of many of the most successful products in the market. With more than 30 years of experience with various formulations and the most extensive R&D facilities for cosmetics in Europe, the department is continually expanding its range of activities and research capabilities.

In addition to the regular lab equipment (regular and sensitive scales, ovens, Brookfield viscosity meter, density meter and pH meter … etc.), the R&D Lab is fully equipped to perform formulation and samples on different scales.

Examples of the equipment include:

Production

At Soliteint we ensure top notch quality products at the least possible lead time owing to our huge capability for mixing, emulsification in addition to filling and packaging technologies.

Our facility can produce all kinds of cosmetics and personal care products like, cream, toothpaste, shampoo, lotions, gels, liquids, oils, sticks, serums and hydroalcoholic products.

Our facility is supplied by all utilities to ensure proper supply to the production machines.

Production Machines

- 6 Kg capacity under vacuum mixing machine

- 20 Kg capacity under vacuum mixing machine

- 100 Kg under vacuum mixing machine

- 150 Kg Color cosmetics micing machine

- 300 Kg under vacuum mixing machine

- 900 Kg Liquid mixing tank

- 500 Kg under vacuum mixing machine

- Tube filling machines

- Jar filling machine

Our Machinery

Vaccum Mixing machinery

All Mixers Are Synchronized with Auxiliary Tanks To Serve As Melting And Aqueous Tank Where Transfer Is Controlled Through Automated Valve And Operated Through Machine PLC.

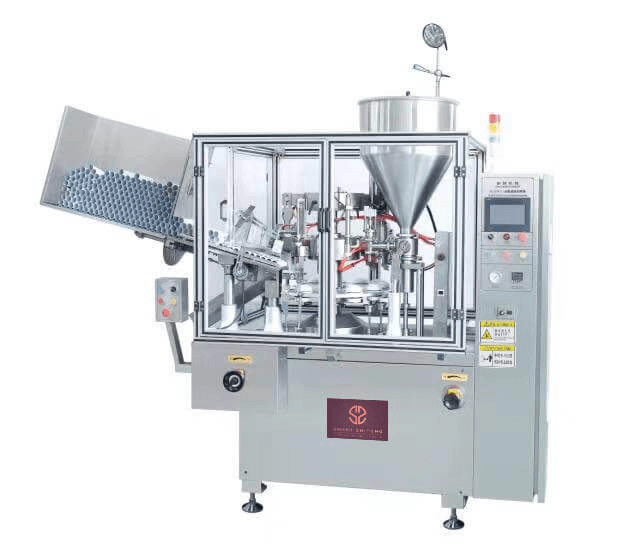

Tube filling machinery

Plastic, laminate, aluminium tubes filling and sealing at high efficiency and quality.

Jar filling machine

30 g to 300 g filling grammage.

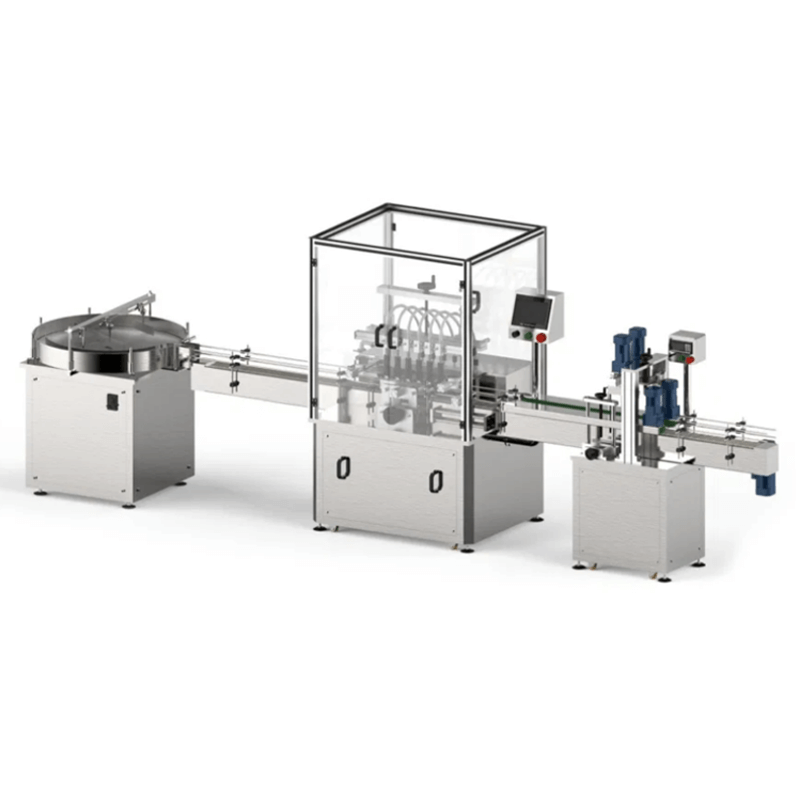

Bottle filling machine

30 g to 500 g filling grammage.

Semiautomatic filling machinery

Multiple semiautomatic filling machines for all cosmetics products, cream/liquids/shampoos/powders

• Up to 100 bottles/min

• Filling from 2 g to 600 g jars

Auxiliary Packaging Machinery

• Labelling machines

• Cellophane overwrapping machine

• sleeve overwrapping machines

• Automatic shrink wrapping machines